WHAT IS A STEEL STRUCTURE?

A steel structure is a metal structure that is made up of structural steel components connected to each other to carry loads and provide rigidity. Because of the high strength of the steel, these structures are reliable and require less raw materials than some other types of structures such as concrete.

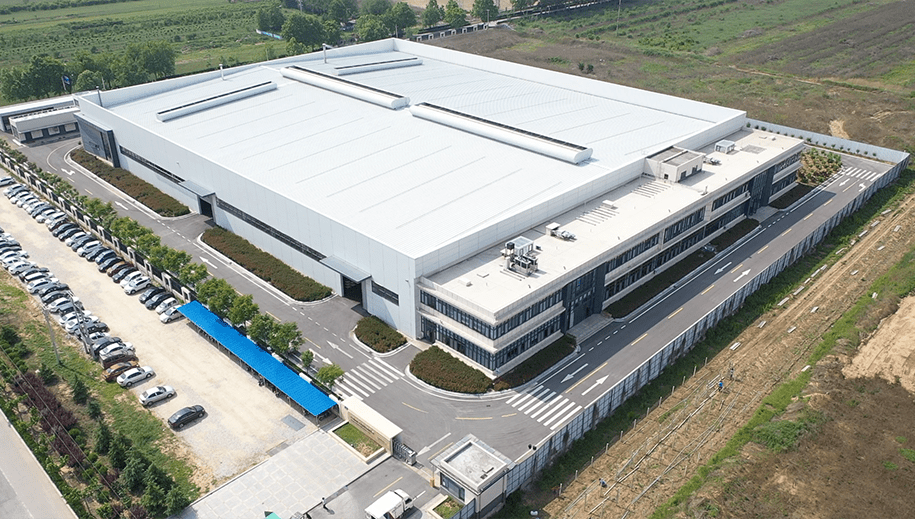

In modern construction, steel structures are used for almost every type of structure including heavy industrial buildings, high-rise buildings, equipment support systems, infrastructure, bridges, towers, heavy industrial plants, churches, poultry houses, warehouses, office buildings, workshops, exhibition hall, etc.

The concrete structure, on the other hand, is a composite material, consisting mainly of cement, water, and aggregate (gravel, sand, or rock). when these materials are mixed together, they form a workable paste which then gradually hardens over time.

Advantages of steel structure building than a concrete structure

- In steel structures when correctly built and maintained, the life expectancy of a steel building can exceed 100 years. steel building lasts longer than concrete or wood because durable steel better resists common causes of deterioration (mold, termites, moisture) and more effectively stands up to natural disasters than wood or concrete buildings.

- In steel structure, the total weight of the building is light: about half of the concrete structure’s weight, which can reduce the foundation cost.

- Fast construction: the construction period is shortened by 1/4 to 1/6 compared with the traditional concrete structure.

- Strong flexibility: large open span design, indoor space can be divided into multiple programs to meet the different needs of the owners. In particular, the exhibition center can adopt the pipe truss structure, which is easy to realize the large space function, increase the space height, and has the characteristics of beauty and comfort.

- Good energy-saving effect: the wall is made of factory-made steel components or light-weight energy-saving standardized C-shaped steel, square steel, sandwich panel, high processing precision, good thermal insulation performance, and good earthquake resistance.

- Good environmental protection effect: greatly reduce the amount of sand, stone, ash, environmental protection, and energy-saving during construction.

- Constructability: The strength, stiffness, toughness, and ductile properties of structural steel allow it to be fabricated into an endless variety of shapes. Steel structures are assembled by bolting or welding the pieces together on-site as soon as they are delivered as opposed to concrete, which takes weeks to cure before construction can continue.

- Fast delivery: Compared with traditional concrete buildings, precast steel structures can save up to one-third of construction time. The all-steel fabric was cut, welded, drilled, and painted at the factory. It is easy to assemble quickly on-site and transport quickly. The longest transport time for container ships is four to five weeks

Disadvantages of steel structure

- Steel is available only at the steel shops where it’s produced and should be transported for long distances to the construction point, not at all like concrete or different materials that might be accessible right at the point of development.

- Buckling is an issue with steel structures. As the length of the steel member builds, the chances of buckling also increase.

- Indeed though steel is a flexible material, it’s challenging to make field corrections if one or further factors don’t fit meetly. A large portion of the metal structure performs cleave to strict quality assurance procedures guarantee all pieces of a system fit directly. But in fact, it isn’t possible. One can not form it or cut it in the ideal shape on-point once it’s fabricated.

- Steel is a good captain of heat, touches off accouterments in contact, and frequently causes fires, snappily spreading to different parts of a structure. Hence, steel structures may bear redundant fireproofing treatment.

- Due to rust in steel, expensive maquillages are needed to reestablish from time to time so that resistance against severe conditions increments.

All the Advantages & Disadvantages of steel structure are explained to know complete information about steel to suitable to use the steel in a better manner for the construction process.

The characteristics of steel structure

- The steel structure is small and light in weight, convenient for transportation and installation, as well as for assembly, disassembly, and expansion. It is suitable for structures with a large span, high height, and heavy load.

- The steel has high strength, good plasticity and toughness, and strong resistance to impact and vibration.

- Steel has high strength and a light structure. Compared with masonry and wood structures, steel has a higher density but higher strength, so the ratio of density to strength is smaller. Under the same load, the steel structure is better than other structures.

- The high degree of industrialization of steel structure, factory manufacturing, site installation, high processing accuracy, short manufacturing cycle, high production efficiency, and fast construction speed; steel structure buildings have strong platform structures, roof structures, tall background walls, etc. The sense of time and changeable appearance are suitable for expressing the imagination of designers.

- Residual materials and debris generated in steel structure processing and manufacturing and abandoned and damaged steel structures can be re-smelted into steel for reuse. Therefore, steel is called green building materials or sustainable materials.

Leave a Reply